Research and Development

Solid State Fusion and FuseRing in tandem are the natural evolution of pipeline construction.

Patents Granted 6 x USPTOs

DEMO #1

FuseRing's solid-state fusion welding technology offers significant advantages for shipbuilding and submarine manufacturing. By utilizing induction heating and controlled mechanical pressure, FuseRing enables high-integrity welds with minimal heat input, reducing thermal distortion and preserving the metallurgical properties of critical materials like steel and titanium. This precision is particularly beneficial for constructing submarine pressure hulls, where structural integrity is paramount. Additionally, FuseRing's capability for underwater welding and repair aligns with modern naval maintenance needs, allowing for efficient in-situ repairs without the necessity of dry docking. The technology's adaptability to existing welding equipment further facilitates its integration into current shipyard operations, enhancing productivity and reducing costs. Overall, FuseRing presents a transformative approach to submarine construction and maintenance, aligning with the industry's move towards more efficient and reliable manufacturing processes.

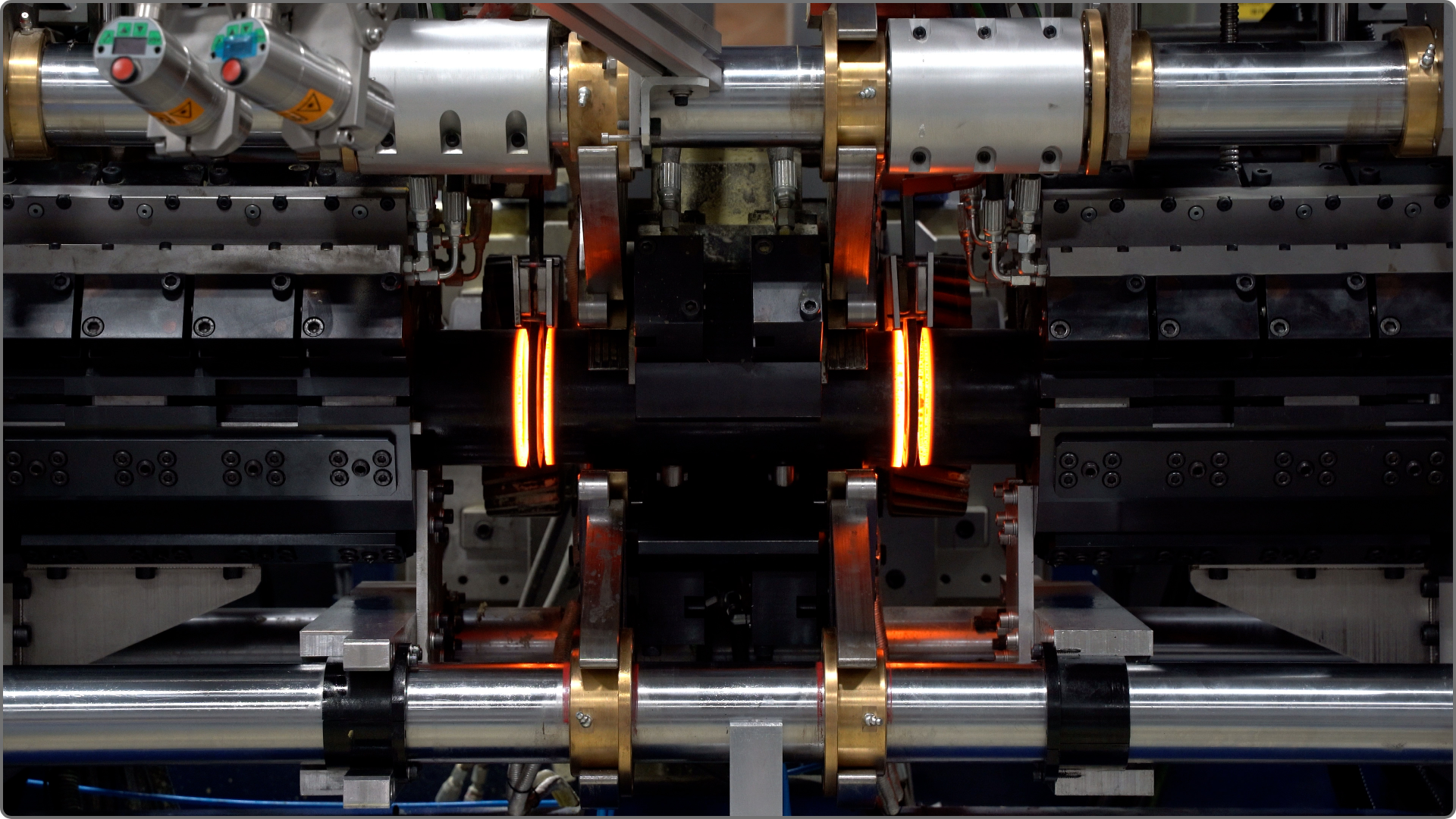

Overview of Induction assisted Friction Process

.png)

Stage 1: Induction preheat (pyrometer thermal feedback)

Stage 2: Retract coil, compress ends

Stage 3: Rotational motion

Solid-State Dynamic Welding Sample:

Regardless of size or thickness, the fundamental science remains the same—induction heating to bring the material to a plastic state, followed by precise shearing and forging to produce a high-integrity, solid-state bond.

.jpg)

Solid-State Welding Technology Enables Flawless Tubular Welds in Nuclear Power Plants

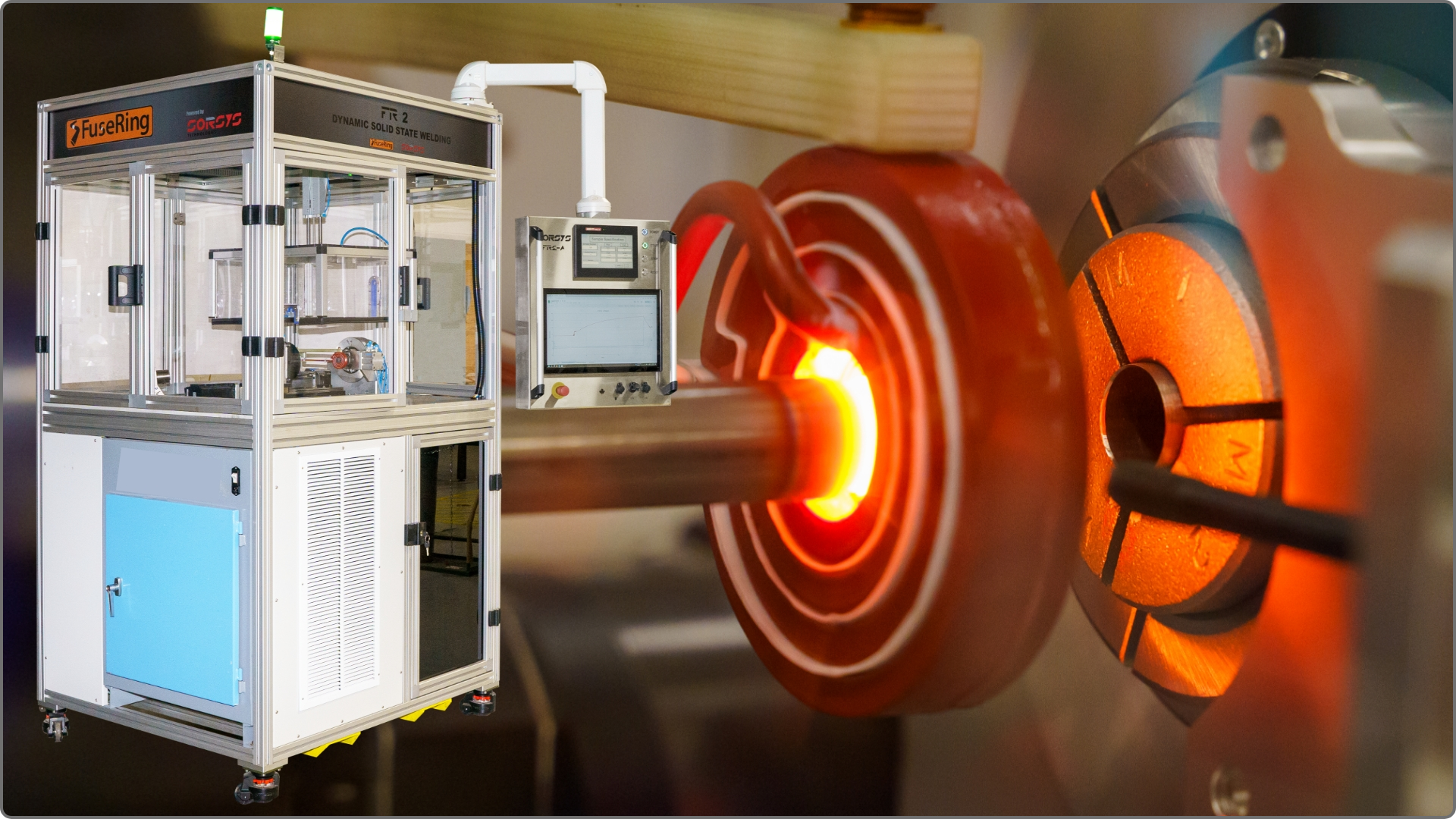

DEMO #2

FuseRing introduces a groundbreaking solid-state fusion welding technique that transforms the landscape of tubular welding in nuclear power plants. By eliminating the need for filler metals, toxic fumes, and extensive heat-affected zones, FuseRing offers a safer, faster, and more reliable method for joining tubular components.

Unlike traditional welding methods, FuseRing employs a unique process that combines induction heating with kinetic energy to achieve seamless, high-strength bonds. This approach not only ensures structural integrity but also significantly reduces weld times, with the entire process completing in 60 seconds. The technology's ability to join both similar and dissimilar materials without compromising quality makes it particularly suited for the stringent demands of nuclear power plant construction and maintenance.

Moreover, FuseRing's innovation addresses the challenges associated with welding non-rotatable components, a common scenario in complex nuclear assemblies. By acting as an intermediary between such components, FuseRing enables consistent and defect-free welds, enhancing overall safety and efficiency in nuclear power plant operations.